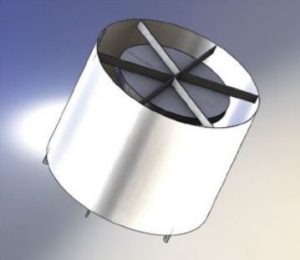

Vent Silencers

In process, petro-chemical and electricity power generation plants there are typically numerous safety and control valves depending on the system configuration. The opening of these valves to vent steam, gas or vapour is accompanied by very high levels of noise. In order to protect employees from excessive plant noise and to comply with statutory regulations, installing vent silencers may reduce accidents arising from shock reactions, eliminate noise-induced hearing damage of personnel and prevent wider environmental noise issues.

Vent silencers are designed to reduce noise level of exhaust piping to the atmosphere for pressurized gaseous fluids, such as air, vapour, natural gas, nitrogen, oxygen, carbon dioxide, etc. They can be installed downstream any device acting as a link between a container of pressurized gaseous fluid and the atmosphere. The vent silencer can also provide high or low back pressure relief for the system ensuring proper operation.

Noise reduction can be attained using two principles: a reactive section to attenuate the low frequencies, providing broad band noise reduction; an absorptive section for high frequency noise mitigation. Vent silencers can be reactive, absorptive or combined type depending on applications and required attenuation, available up to 75 dB(A).

(Standard supply : Butt weld)

(Standard supply : Butt weld) Standard supports are part of bottom plate

Standard supports are part of bottom plate Allows pipe movements due to thermal expansion, avoiding nozzle loads

Allows pipe movements due to thermal expansion, avoiding nozzle loads • Prevents rain entering the silencer

• Prevents rain entering the silencer AGL Torrens, located 18 km from Adelaide CBD on Torrens Island, is the largest power station in South Australia and the largest natural gas fired power station in Australia.

AGL Torrens, located 18 km from Adelaide CBD on Torrens Island, is the largest power station in South Australia and the largest natural gas fired power station in Australia.